Innovations that drive world class Solutions

Since 1918, Dorman Products has been the automotive aftermarket’s pioneering problem solvers. They have released thousands of parts and components that people could once only buy from original equipment manufacturers. By always innovating, Dorman has led the way in growing the aftermarket, providing more opportunity to individuals and businesses who depend on automotive maintenance.

Trending Parts from Dorman

Whats new at Dorman?

Check out the latest guides that go over some of the latest tech Dorman has to offer.

.jpg)

Drivers all over the world recognize Dorman as a pioneer in the automotive field.

Since its founding in 1918, the company has figured out a way to produce high-quality parts for cars, trucks and SUVs at a fraction of the price the competition would ask for.

StockWise Auto is dedicated to supplying you with the best parts for repairs and restoration work, so you'll see multiple component options for your vehicle by no other than Dorman.

Find automotive replacement parts engineered by Dorman's talented specialists right here in StockWise Auto's inventory. Your days of driving across town to a dealership for parts are over.

Dorman is known for creating thousands of parts and systems that are compatible with your favorite vehicle models. Dorman produces over 80,000 components, which is something few manufacturers can state. When you order Dorman products from StockWise Auto, you'll receive technology that's been designed from the ground up by Dorman's specialty groups. Find all the cutting-edge technology you'll need for small or complex jobs by clicking through our impressive catalog.

Why Dorman is a Featured Brand

OFFERING INNOVATIVE ENGINEERING

The engineers at Dorman are motivated by customers nationwide. Dorman creates every product from scratch with the intention of saving you time and money. Whether this is your first repair or you've completed thousands, the company utilizes materials that last for the long haul. StockWise Auto is home to best-selling creations from Dorman which include wheel components, drive shafts, exhaust manifold replacements and engine coolant recovery tanks. Start your repair or restoration task off on the right note.

PAYING ATTENTION TO THE FINE DETAILS

The Dorman team consists of more than 100 engineers to bring products to life. Each stage of production is carefully mapped out so that Dorman auto parts follow the same specifications as the original equipment manufacturer (OEM) installations. Through StockWise Auto, you can find affordable parts made by Dorman for all types of automakers, such as Audi, BMW, Honda, Ford, Nissan, Subaru and GMC.

RIGOROUSLY TESTED

Dorman aftermarket parts undergo numerous tests before the solutions are made available to the public. Engineers create product prototypes to see how automotive parts behave in certain conditions. Select offerings from our store may be subject to tensile strength, hardness, corrosion and hydrostatic burst testing. Dorman is willing to go the extra mile to ensure customer satisfaction which is why StockWise Auto has a growing selection of Dorman parts for your vehicle.

.jpg)

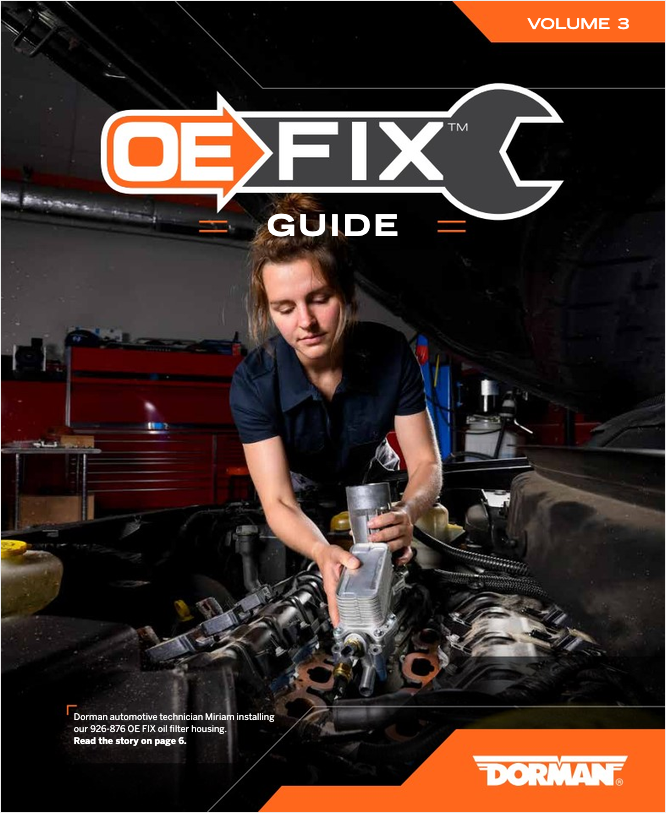

OFFERING AN OE FIX

You can count on Dorman to find and fix flaws in OEM components. The company has made a name for itself producing problem-specific solutions for vehicles. When an OEM misses a critical issue, Dorman steps in with the part you require for a timely repair. These economical parts for sale are better known as OE FIX components. Prevent future breakdowns with the assemblies or parts you require from StockWise Auto.

ADVANCED ELECTRONICS

The electrical engineers at Dorman take inspiration from OEM parts. Workers will analyze control modules, printed circuit boards and design aspects to see how they can enhance functionality and lifespan. If necessary, an in-house software team develops original technology to interact with various sensors and processors for a new car part. Drivers can shop the StockWise Auto inventory for parts intended for specific vehicles.

Modern vehicles increasingly rely on electronic modules, as well as mechatronics, that combine electronics with mechanical parts. To continue being a leader in these new technologies, in 2018 Dorman products acquired Flight Systems Automotive Group in Lewisberry, PA, one of the industry’s leading manufacturers and remanufactures in complex electronics and diesel mechatronics. Their contributors use state-of-the-art technology to build brand new modules, as well as restore the functionality of previously used parts.

.jpg)

Top Products from Dorman

Top Categories from Dorman

SHOP DORMAN PRODUCTS AT STOCKWISE AUTO TODAY

StockWise Auto has the automotive parts you're looking for to get the job done correctly. Be sure to browse our selection of Dorman products, as we're always adding the brand's latest creations to our store. Place your order with us today, and contact us for additional product information.